COR-TEN¬ģ Steel

.jpg)

COR-TEN¬ģ steel became popular among architects. There are three reasons for¬†that:

- Corten needs zero maintenance.

- Corten changes colors and becomes more beautiful year after year.

- Corten is a sustainable material

COR-TEN¬ģ was invented for¬†building coal carriages in¬†1930s America. Corten steel plate might look like it‚Äôs rusty. Still, thanks to¬†clever manipulation in¬†its processing, the¬†outer oxidization protects the¬†steel from further corrosion, as¬†well as¬†making it look excellent indeed. There‚Äôs no¬†need to¬†paint Corten, and¬†it changes the¬†color itself over time. Last century Corten was the¬†metal of¬†choice for¬†containers and¬†other shipping elements. More recently, though, it‚Äôs become the¬†material of¬†choice for¬†many artists, architects, and¬†interior designers. Corten steel cladding is popular and¬†often used for¬†buildings, giving it a¬†tough coating against the¬†elements and¬†an¬†industrial-looking edge.

How is it made

Weathering steel is an alloy, which is what makes it so resistant to the elements. The addition of nickel, copper, and chromium at the production stage means that a protective patina will develop on the surface of the metal over time.

Patina Formation Process

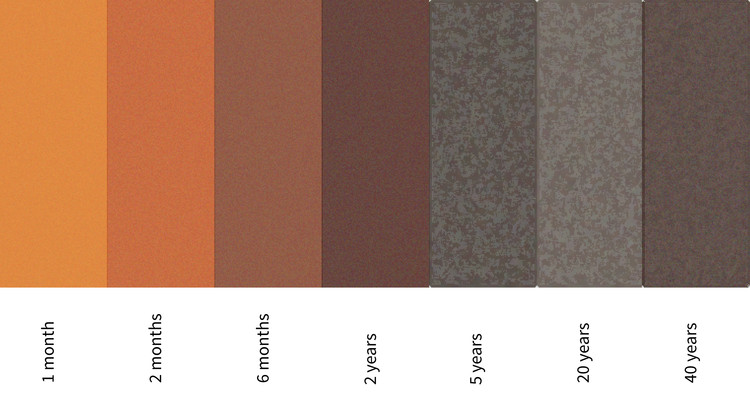

Under the influence of the wet and dry cycles, the rusting process of this steel initially proceeds in the same way as with ordinary metal. However, over time, the rust develops into a layer of patina, and its color changes from orange-brown to light or dark brown.

The¬†rate of¬†change and¬†the¬†final color depends on¬†the¬†ambient atmospheric conditions and¬†contaminants in¬†the¬†air¬†‚Äď sulfur will accelerate the¬†oxidation process and¬†give the¬†patina a¬†darker color. Frequent changes in¬†dry and¬†wet conditions will also accelerate oxidation.

types of¬†COR-TEN¬ģ

There are 5 types of¬†corten: cold-rolled COR-TEN¬ģ A, hot-rolled COR-TEN¬ģ A, COR-TEN¬ģ B, C, and¬†D. You can find more on¬†ssab website

With which materials to use

Wood, glass, concrete, and bricks are the perfect combinations for corten steel. As always in architecture, you are allowed to use up to 3 different materials for the façade. The most popular combination is: concrete, glass, and corten steel.

perforation

Corten steel Sheet is also excellent for¬†a¬†variety of¬†punching styles. Round, square or¬†rectangular holes, texts, logos, images¬†‚Äď the¬†possibilities are practically unlimited. The¬†backlighting of¬†the¬†panels will highlight the¬†selected design.

Price

I have found two types of¬†corten steel¬†‚Äď the¬†normal one and¬†the¬†weathered corten steel. I guess the¬†weathered steel has higher protection from rain etc.

The corten weathered steel sheet costs from 41£ (55$) per m2 with 1.5mm width to 200£ (250$) with a width of 6 mm.

The corten weathered steel sheet costs from 120£ (150$) per m2 with 1.5mm width to 350£ (450$) with a width of 6 mm.

However, this is a retail price; the wholesale price will be lower. The company that I used to get the price is located in the UK; their prices for labor are high. Therefore, in Russia, this technology costs less.

note: the dollar prices are not precise, and the price excludes VAT